|

Basic Information |

|

|

Standard |

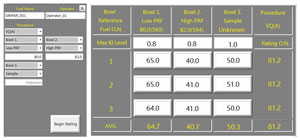

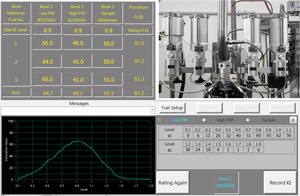

ASTM D2699 RON, ASTM D2700 MON |

|

Working Range |

40-120 octane number |

|

Operation Conditions |

|

|

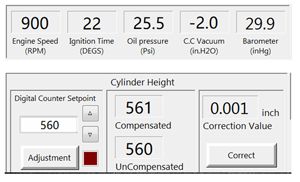

Engine Speed (Motor) |

900±9 rpm |

|

Engine Speed (Research) |

600±6 rpm |

|

Ignition Timing (Motor) |

Variable as Cylinder Height (C.R.) is Changed |

|

Ignition Timing (Research) |

13° BTDC |

|

Intake Air Temperature (Motor) |

38°C±2.8°C |

|

Intake Air Temperature (Research)*1 |

52°C±1°C at Std. Barometric Pressure, |

|

Intake Mixture Temperature (Motor)*2 |

149°C±1°C |

|

Intake Air Humidity |

25-50 Grains of Water/lb. Dry Air |

|

Crankcase Oil Temperature |

57°C±8°C |

|

NOTE:*1 See ASTM D2699 for details. |

|

|

NOTE:*2 See ASTM D2700 for details. |

|

|

Engine Information |

|

|

Compression Ratio (C.R.) |

4:1-18:1 |

|

Cylinder Bore (Diameter) |

82.55 mm (Standard) |

|

Stroke |

114.30 mm |

|

Carburetor Venturi (Research) |

14.30 mm |

|

Intake Valve Clearance (Hot) |

0.20 mm±0.025 mm |

|

Exhaust Valve Clearance (Hot) |

0.20 mm±0.025 mm |

|

Intake Valve Opens Timing |

10°±2.5° ATDC |

|

Intake Valve Closes Timing |

34° ABDC |

|

Exhaust Valve Opens Timing |

40° BBDC |

|

Exhaust Valve Closes Timing |

15°±2.5° ATDC |

|

Crankcase Oil Pressure |

172 kPa - 207 kPa |

|

Function Information |

|

|

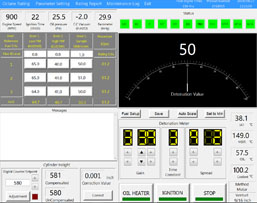

Operating Panel |

SXCP Digital Control Panel |

|

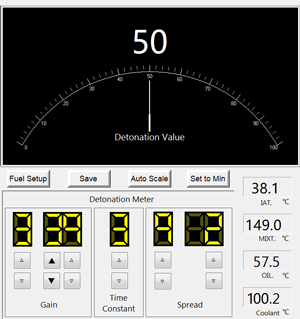

Knock Meter |

Automated Digital Knock Meter |

|

Compression Ratio Adjustment |

Motor-Driven (Auto-Adjust) |

|

Compression Ratio Display Device |

Dual Indicator & Digital Counter |

|

Engine Speed Conversion |

Dual-Speed Motor |

|

Carburetor |

Four-Bowl Falling Level (with a cooling function) |

|

Ignition Timing Display |

Digital (Auto-Set) |

|

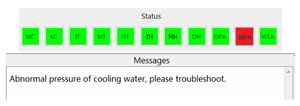

Crankcase Pressure Display |

Yes |

|

Electronic Barometer |

Yes |

|

Oil Pressure Display |

Yes |

|

Oil Temperature Display |

Yes |

|

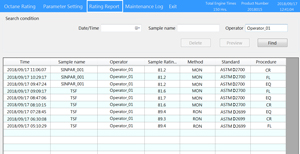

Report Generation |

Yes |

|

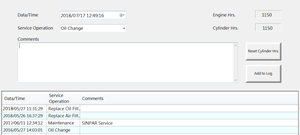

Maintenance Log |

Yes |

|

Air Humidity Control System |

Yes |

|

Exhaust Surge Tank System |

Yes |

|

Unit Safety System |

Yes |