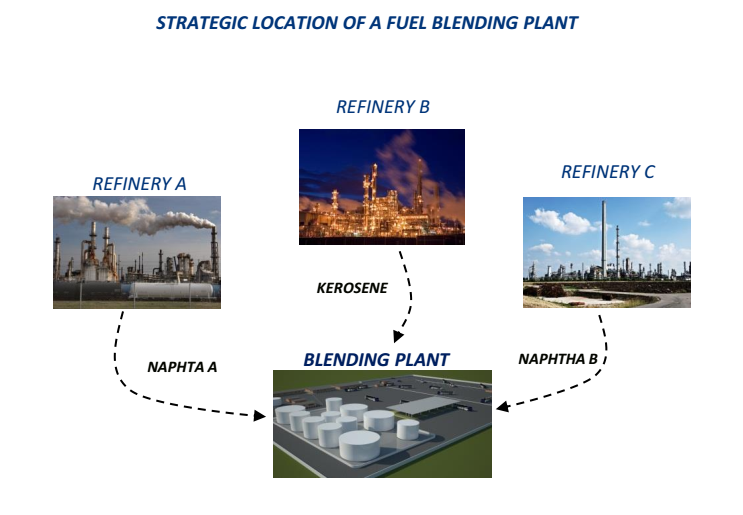

Fuel blending is a consolidated activity in many countries. It requires the selection and combination of intermediary petroleum byproducts, acquired in different refineries, so as to optimize production and quality.

The products are purchased from different refineries because each type of petroleum and refining process generates different qualities of byproducts.

Gasoline is composed of many different hydrocarbons. Crude oil enters a refinery, and is processed through various units before being blended into gasoline. A refinery may have a fluid catalytic cracker (FCC), an alkylate unit, and a reformer, each of which produces gasoline blending components. Alkylate gasoline, for example, is valuable because it has a very high octane, and can be used to produce high-octane (and higher value) blends. Light straight run gasoline is the least processed stream. It is cheap to produce, but it has a low octane. The person specifying the gasoline blends has to mix all of the components together to meet the product specifications.

Gasoline blending components:

Naphthas (e.g., straight-run gasoline, alkylate, reformate, benzene, toluene, xylene) used for blending or compounding into finished motor gasoline. These components include reformulated gasoline blendstock for oxygenate blending (RBOB) but exclude oxygenates (alcohols, ethers), butane, and pentanes plus.