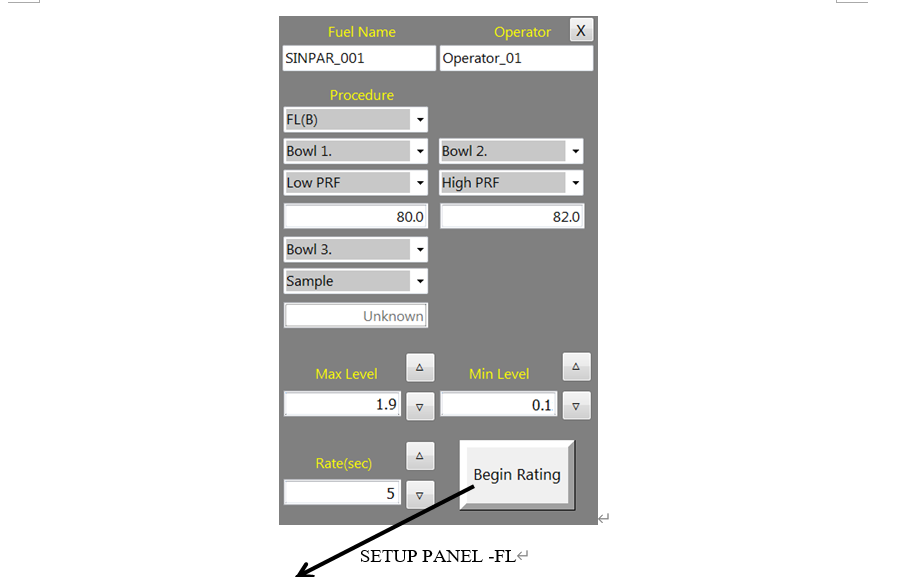

Octane cfr engine with digital control panel is equipped with the Falling Level Model program for operating PROCEDURE B (Bracketing-Dynamic Fuel Level) in ASTM D2699 & ASTM D2700. SINPAR octane engine with SXCP digital control panel provides Falling Level Program to allow determining maximum knock intensity without manual adjustment of fuel level. Falling level program is used with a Four-Bowl Falling Level Carburetor. It has a more sensitive fuel flow adjustment mode for obtaining more accurate result and delivers an efficient and accurate falling level test. The operator can efficiently and accurately operate an octane cfr engine to run a falling level test, by PROCEDURE B, in ASTM D2699 and D2700.

Four-Bowl Falling Level Carburetor is equipped on the octane cfr engine. That is available in multiple jet and venturi sizes for all applications. Fuel flow control system is used to permit adjustment of fuel-air ratio. The fuel level that produces maximum Knock Intensity is from 0.7 in. to 1.7 in. Four Bowls are offered. The fourth bowl is equipped with a cooling system for testing highly volatile fuel octane.

The Falling Level Program is built in octane operating software. XCP cfr octane engine touch-screen panel of octane engine with easy-to-follow guidance simplifies the operation process.

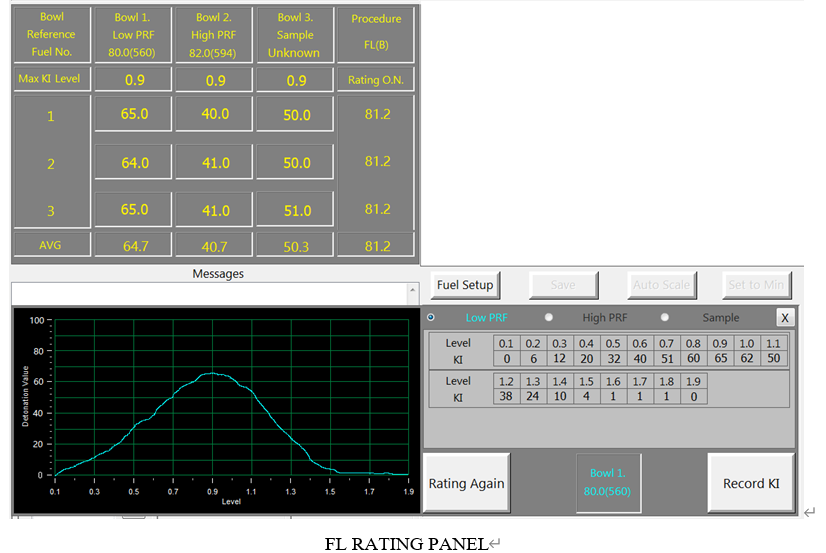

After clicking the “Begin Rating” button, the fuel level in sight glass will drop and the rate counter will elapse. The FL program will automatically run and record K.I. value for each associated fuel level based on the Rate set. Once all fuel levels with KI have been recorded for the first fuel, the “Record KI” button will change to “Save Record”. Click the “Save Record” to save this record. The Max KI Level and Max KI values will be recorded automatically on rating data screen (see below figure).

If necessary, you can click “Rating Again” to perform this single rating again. Continue to rate the second and third fuels in turn following the same process.

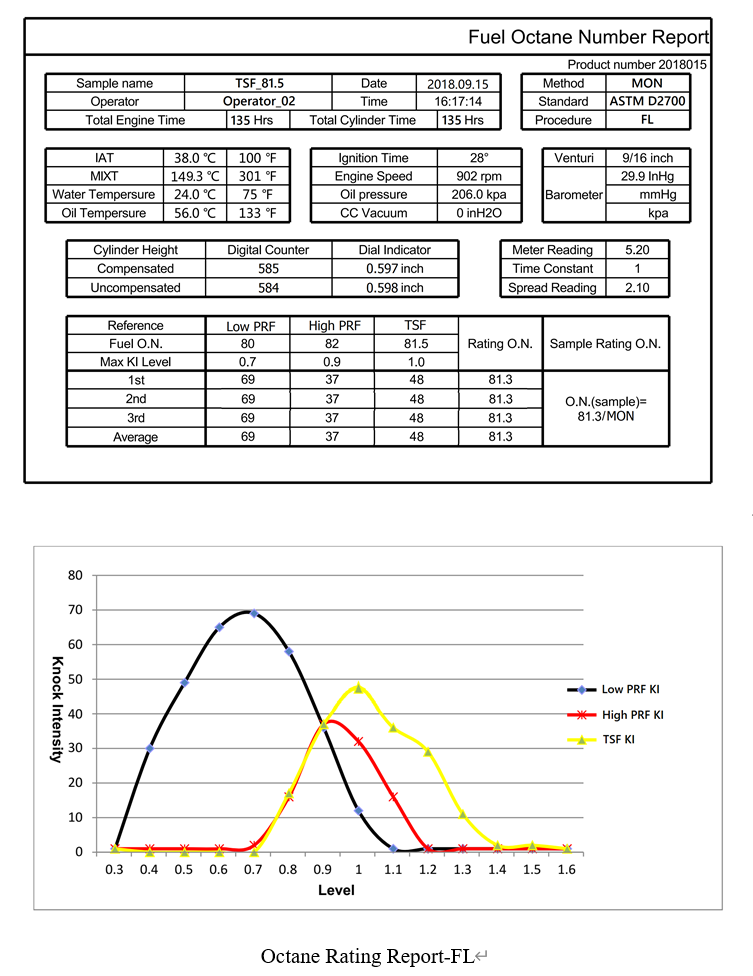

When all the fuel ratings are complete, the software will calculate and display the results and the relational graph between K.I. and fuel Level. Click the “Save” button to save the rating data to the report.