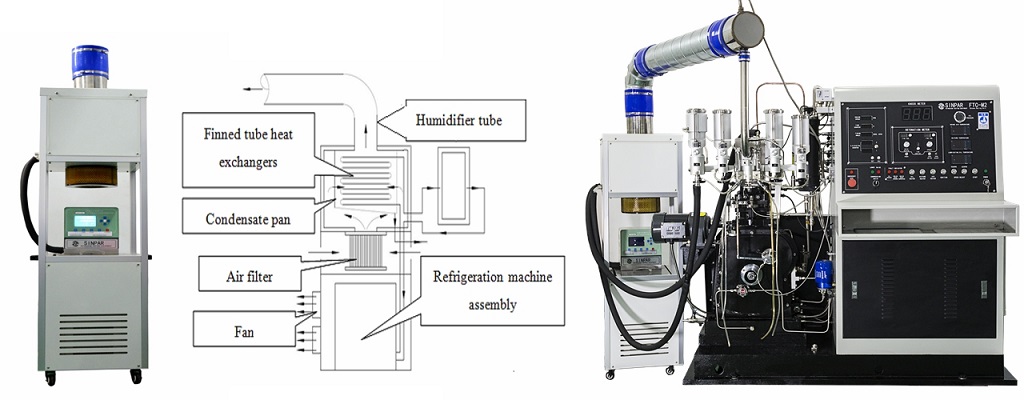

The system provides constant filtered air, which is dehumidified through pipes and finned cooling heat exchangers in which refrigerant circulates.

The system is installed in a movable industrial cabinet, suitable for different laboratory space conditions.

Applicable Standard

|

ASTM D2699, ASTM D2700, ASTM D2885

|

Application

|

For RON and MON Methods Octane Engines |

Operation Mode

|

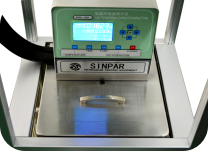

Digital control panel |

Temperature Cooling Range

|

From laboratory ambient to -10°C |

Temperature Stability

|

±0.5°C |

Intake Air Chilling

|

1°C-3°C |

Cooling Fluid Volume

|

5L liquid |

Cooling Medium

|

Glycol |

Circulation Mode

|

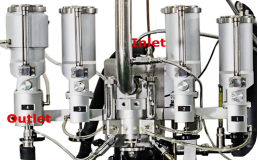

A pump circulates the coolant from reservoir to engine carburetor |

Connection Mode

|

Quick couplings |

Power Switches

|

A main power switch and a pump power switch |

Power Supply

|

220V 50Hz/60Hz with Single Phase |

Safety System

|

Real-time Monitoring for Fluid Level & Temperature; System Electrical Protection |

Weight

|

95.00 kg |

Dimension

|

46x46x160cm (without humidifier tube) |