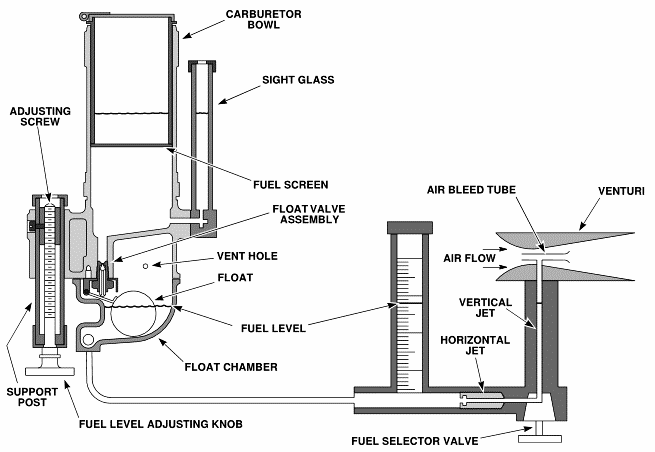

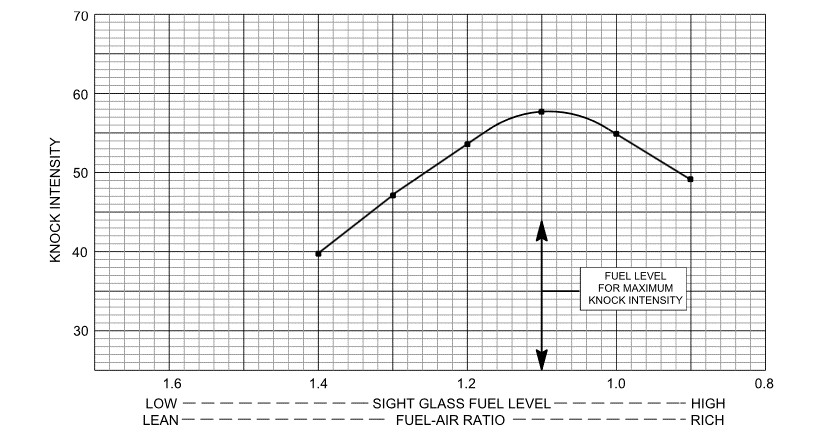

With the octane rating engine operating at a cylinder height that causes knock, variation of the fuel-air mixture has a characteristic effect, typical for all fuels. ASTM D2699 RON and ASTM D2700 MON test methods specific that each sample fuel and PRF shall be operated at the mixture condition that produces the maximum K.I. The octane rating engine carburetor, utilizing a single vertical jet, provides a simple means to monitor a measure of fuel-air ratio using a sight glass that indicates the fuel level in the vertical jet.

Low fuel levels relate to lean mixtures and higher levels to rich mixtures. Fuel level changes are made to determine the level that produces the maximum knocking condition. To maintain good fuel vaporization, a restrictive orifice or horizontal jet is utilized. So that the maximum knock condition occurs for fuel levels between 0.7 in. and 1.7 in. referenced to the centerline of the carburetor venturi. The mechanics for varying the fuel mixture can be accomplished using various approaches.

Octane rating fuel-air ratio is not only dependent on the fuel level, but is also affected by the friction related to fuel flow in the passages leading to the vertical jet. Providing interchangeable horizontal jets allows selection of a jet orifice size, that causes the critical fuel level required for the test procedure (fuel level for maximum knock intensity) to be set within specified limits on the sight glass.

Venturi Size:

Research Method:9/16 inch throat diameter

Motor Method:Sea level – 500m altitude=9/16 inch throat diameter

500m – 1000m altitude=19/32 inch throat diameter

Above 1000m altitude=3/4 inch throat diameter

Air Bleed Tube: Centered in the venturi throat.

Horizontal Jet Size:

Research Method = 1.2 diameter

Motor Method = 1.05 diameter

NOTE: Jet sizes are typical for units located near sea level. At altitude locations, select the jet required for proper carburetion based on trial and error tests to determine the size that produces fuel levels for maximum knock intensity within the fuel level limits. Higher altitudes will generally require larger jet sizes.

NOTE: Fuel Level for Maximum Knock Intensity: With the octane rating engine operating at a compression ratio high enough to establish knocking conditions, adjust the fuel level to the value that produces maximum knock intensity. This fuel level shall be between 0.7 and 1.7 inches as indicated in the sight glass. If the level is above 0.7 inches, it is necessary to replace the horizontal jet with one that has a larger orifice hole. If the level for maximum knock is lower than 1.7 inches, it is necessary to replace the horizontal jet with one that has a smaller orifice hole.